The Industrial Significance Of Laser Flatness Measurement

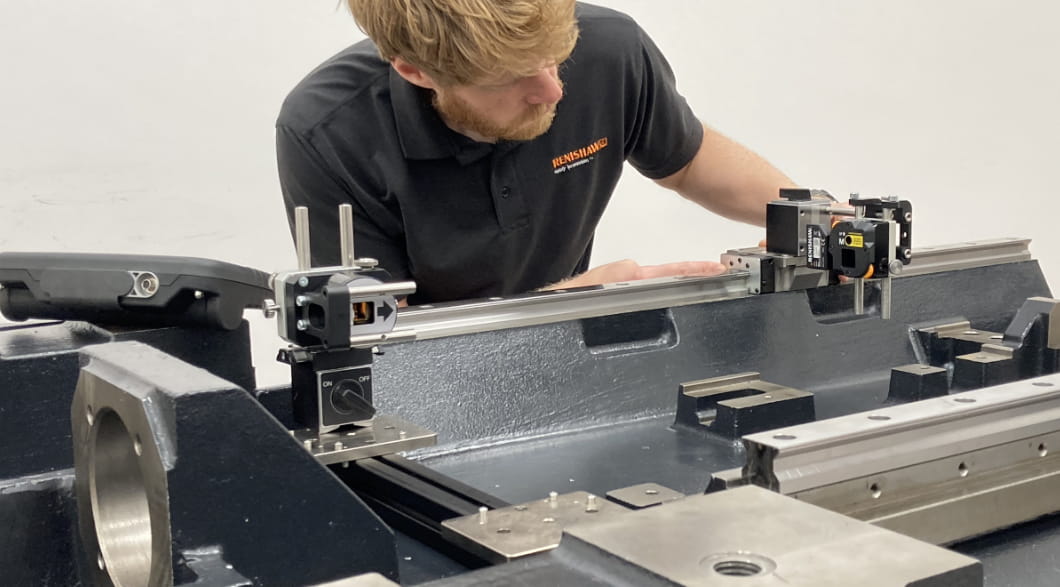

A hot topic in today’s manufacturing market is laser flatness measurement. More and more companies are choosing to invest in this innovative technology due to its proven reliability and productive capabilities.

The ability of a laser flatness gauge to detect both dimensional deviations and surface defects is extremely useful. It’s used in a variety of industries, including aerospace, automotive, and manufacturing, to ensure the quality and consistency of products.

The Manufacturing Sector

Laser flatness evaluation helps gauge the straightness of products such as machine tool beds, printing plates, and semiconductor wafers. Machine tool beds must be extremely flat to examine accurate cutting and grinding of materials.

Meanwhile, printing plates must be flat to guarantee accurate printing of text and images. Semiconductor wafers must be flat to ensure the accurate processing of electronic devices. All these are just a few examples of the many industries reliant on flatness technology to guarantee quality and consistency.

Construction Industry

Precision maintenance is a vital element of the construction industry to assure the accuracy of floors, walls, and other surfaces. Floors must be flat in order to maintain the safe and efficient movement of people and materials. Walls, meanwhile, must be straight to ensure proper alignment of doors and windows.

The Aeronautical Industry

In aerospace manufacturing, flatness measurement helps identify the accuracy of aircraft components, such as wing and fuselage panels. These components must be extremely flat and smooth to ascertain efficient aerodynamic performance. It also improves the accuracy of landing gear and other components that must function correctly at high speeds and altitudes.

Automobile Production

In the automotive industry, flatness measurement helps secure the precision of car body panels and other components. Car body panels must be extremely flat and smooth to ensure a good aerodynamic performance and a sleek appearance. It also measures the accuracy of wheels, brakes, and other parts of various vehicles.

Conclusion

Laser flatness measurement is a critical tool for testing the quality and consistency of products across many different industries. It is a precise and accurate method of determining the flatness of a surface. It provides manufacturers with the ability to ensure that their products meet the required specifications.

It’s essential for efficient, dynamic performance, proper functioning of critical components, and accurate cutting, grinding, printing, and processing of materials. With the ability to detect even the smallest deviations in surface flatness, it’s an essential tool in ensuring product quality.

Related Source: Belt Pulley Alignment , Laser Shaft Alignment Tool

Copyright © Rain Stone LLC All Rights Reserved