How EasyLaser Alignment Systems Increase Productivity

Easylaser alignment systems are essential for any business that wants to increase productivity and reduce downtime. With laser alignment, you can achieve accurate, repeatable measurements quickly and easily – without the need for expensive, specialized equipment.

Easy laser alignment systems are perfect for factories, machine shops, and other industrial businesses. In fact, they are so versatile that they can be used in a wide range of applications, from checking the alignment of conveyor belts to the alignment of pumps and motors.

Background:

Easy laser alignment systems use lasers to take highly accurate measurements. This means that there is no need for expensive, specialized equipment. Its alignment is much faster than traditional methods, such as tape measures or levels.

Advantages of a Laser Alignment System

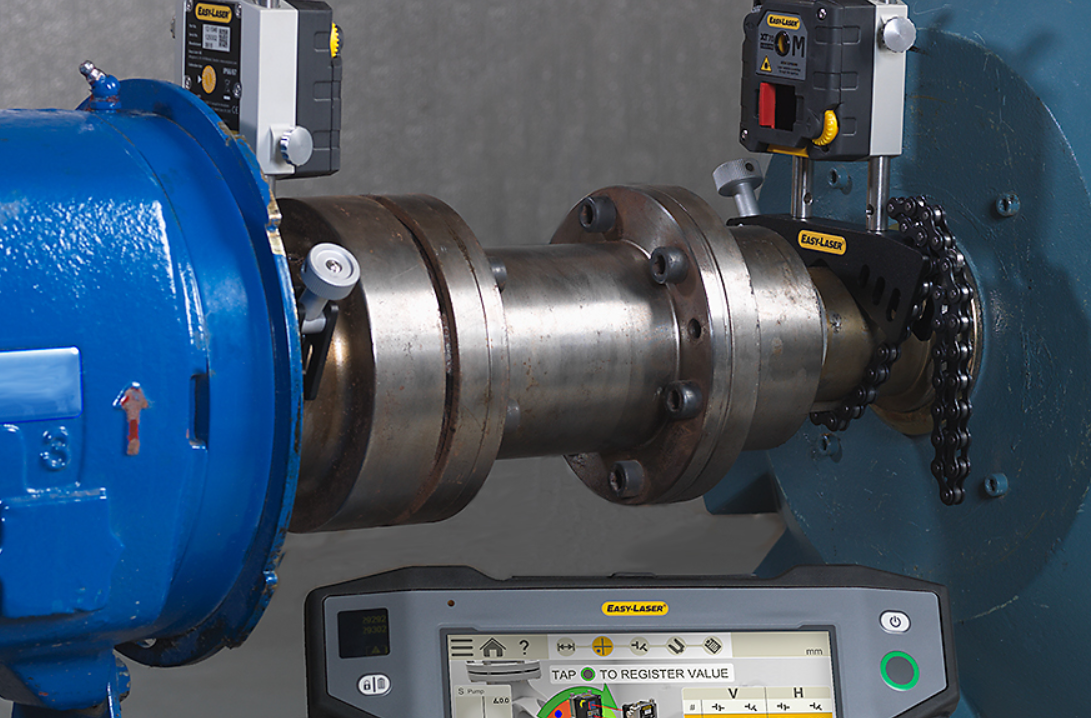

A laser alignment system is a device that helps in the alignment of machinery. It is used to align the tools, axes and other parts of the machine with each other in a way that they are parallel to each other and perpendicular to the surface on which they rest.

A Cardan shaft alignment system can make sure that all the components are aligned correctly within minutes.

It can be a great investment for companies who want to save time and money.

How EasyLaser Alignment Systems Work:

Easy laser alignment systems emit a laser beam that is reflected off of a target surface. The reflected beam is then detected by a sensor, which calculates the distance between the laser and the target surface. ByRepeatable measurements can be taken quickly and easily – without the need for expensive, specialized equipment.

How EasyLaser Alignment Systems Increase Productivity:

Easy laser alignment systems increase productivity in a number of ways. First, they allow for accurate, repeatable measurements to be taken quickly and easily. This means that there is no need for expensive, specialized equipment. This alignment is much faster than traditional methods, such as tape measures or levels.

Case Study:

A leading manufacturer of automotive parts was using traditional methods, such as tape measures and levels, to align their conveyor belts. This resulted in significant downtime and lost production due to inaccuracies and slow measurements. The company decided to switch to an easy laser alignment system. After doing so, they were able to take accurate, repeatable measurements quickly and easily – without the need for expensive, specialized equipment. As a result, they were able to reduce downtime and increase productivity.

Conclusion:

Easy laser alignment systems are essential for any business that wants to increase productivity and reduce downtime. With this alignment, you can achieve accurate, repeatable measurements quickly and easily – without the need for expensive, specialized equipment. For more information visit our Website.

Copyright © Rain Stone LLC All Rights Reserved