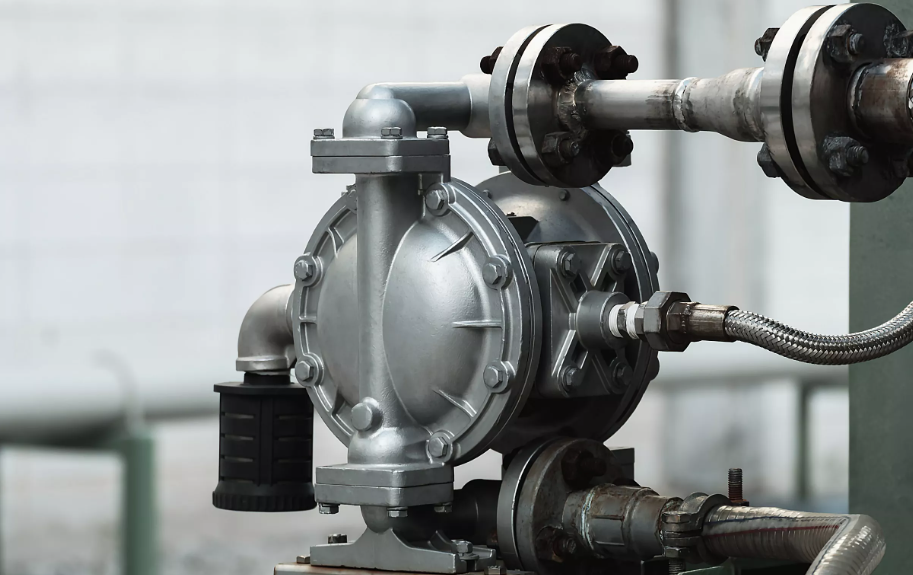

The Benefits of Using Diaphragm Pumps in Industrial Settings

In the realm of industrial fluid handling, diaphragm pumps stand out as versatile and reliable equipment. These pumps offer numerous advantages that make them indispensable in various industrial applications.

1. Versatility in Fluid Compatibility

Diaphragm pumps are renowned for their ability to handle a wide range of fluids, from viscous liquids to abrasive slurries and even delicate chemicals. This versatility is crucial in industries such as chemical processing, wastewater treatment, and pharmaceutical production where different fluids need to be pumped without risk of contamination or degradation.

2. Durability and Longevity

One of the standout features of diaphragm pumps is their robust construction, which contributes to their longevity and reliability. These pumps are designed to withstand harsh operating conditions, including high pressures and temperatures. This durability reduces maintenance costs and downtime, making them a cost-effective choice for industrial operations.

3. Simplicity in Maintenance

Unlike some other types of pumps that require intricate maintenance procedures, diaphragm pumps are relatively simple to maintain. The design often allows for easy access to key components, facilitating quicker inspections and repairs. This simplicity not only saves time but also enhances operational efficiency.

4. Excellent Containment and Safety

For industries handling hazardous or toxic fluids, containment is critical to prevent leaks and spills that could pose environmental risks or jeopardize worker safety. Diaphragm pumps excel in this regard due to their leak-free operation and ability to handle fluids without exposing them to external contaminants.

5. Energy Efficiency

Modern diaphragm pumps, such as those from Davies Pumps, are engineered for optimal energy efficiency. They incorporate advanced technologies that reduce power consumption without compromising performance. This efficiency not only lowers operational costs but also aligns with sustainability goals by minimizing energy consumption and reducing carbon footprints.

6. Self-Priming Capability

Another significant benefit of diaphragm pumps is their self-priming capability. This feature allows the pump to start and operate efficiently without the need for manual priming, which can be a cumbersome and time-consuming process. Self-priming pumps can handle air and liquids interchangeably, ensuring smooth operation even in applications where the fluid supply is intermittent.

Conclusion

Diaphragm pumps offer unmatched versatility, durability, ease of maintenance, safety, and energy efficiency in industrial settings. Their ability to handle diverse fluids and operate reliably under challenging conditions makes them indispensable across various industries. Whether pumping corrosive chemicals in a processing plant or handling abrasive materials in mining operations, diaphragm pumps consistently deliver superior performance and cost-effectiveness.

Copyright © Rain Stone LLC All Rights Reserved