Enhancing Productivity with Copper Laser Cutting Techniques

In the realm of metal fabrication, copper is renowned for its conductivity, corrosion resistance, and aesthetic appeal. However, working with copper presents unique challenges due to its high reflectivity and thermal conductivity. This is where copper laser cutting techniques come into play, offering a versatile and efficient solution for processing copper materials. Let’s delve into how these cutting-edge techniques can enhance productivity and elevate your fabrication capabilities.

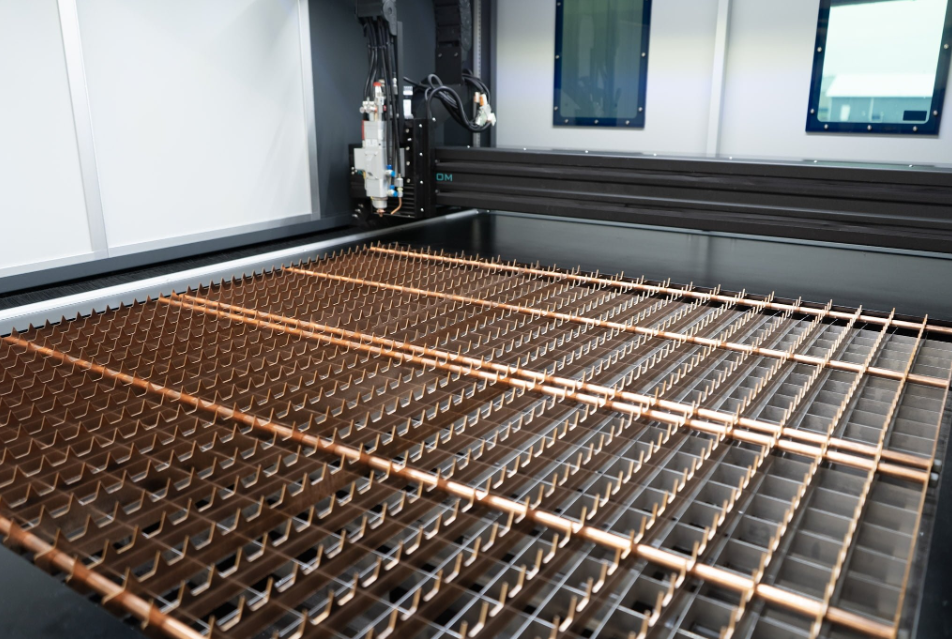

Understanding Copper Laser Cutting

Copper laser cutting utilizes high-powered laser beams to precisely and efficiently cut through copper sheets or components. Unlike traditional cutting methods, such as mechanical sawing or milling, laser cutting offers unparalleled precision and versatility. The intense heat generated by the laser beam vaporizes the material, resulting in clean, smooth edges with minimal distortion or heat-affected zones.

Advantages of Copper Laser Cutting

Precision and Accuracy

One of the key advantages of copper laser cutting is its exceptional precision and accuracy. The focused laser beam can achieve intricate cuts and intricate patterns with micron-level precision, allowing for complex designs and tight tolerances. This level of precision ensures consistency and quality in the finished products, minimizing waste and rework.

Efficiency and Speed

Laser cutting is significantly faster than traditional cutting methods, making it ideal for high-volume production runs. The non-contact nature of the process eliminates the need for tool changes or setup adjustments between cuts, reducing downtime and increasing throughput. With copper laser cutting, businesses can achieve shorter lead times and meet tight deadlines without sacrificing quality.

Versatility and Flexibility

Copper laser cutting is highly versatile and adaptable to a wide range of applications and industries. Whether it’s producing intricate components for electronics, precision parts for aerospace, or decorative elements for architectural projects, laser cutting can handle various shapes, sizes, and thicknesses of copper materials. This flexibility allows businesses to explore new design possibilities and respond quickly to changing market demands.

Minimized Material Waste

Traditional cutting methods often result in significant material waste due to kerf width and inefficiencies in the cutting process. In contrast, it produces narrow kerfs and generates minimal scrap, maximizing material utilization and reducing costs. Additionally, the precision of laser cutting minimizes the need for secondary processing or finishing operations, further reducing waste and improving overall efficiency.

Conclusion

In conclusion, copper laser cutting techniques offer a host of advantages that enhance productivity and efficiency in metal fabrication processes. From precision and accuracy to speed, versatility, and minimized material waste, laser cutting is a game-changer for businesses working with copper materials. By embracing these cutting-edge techniques, businesses can unlock new opportunities, streamline operations, and stay ahead in today’s competitive marketplace.

Copyright © Rain Stone LLC All Rights Reserved