From Misaligned to Streamlined: Belt Pulley Alignment Solutions

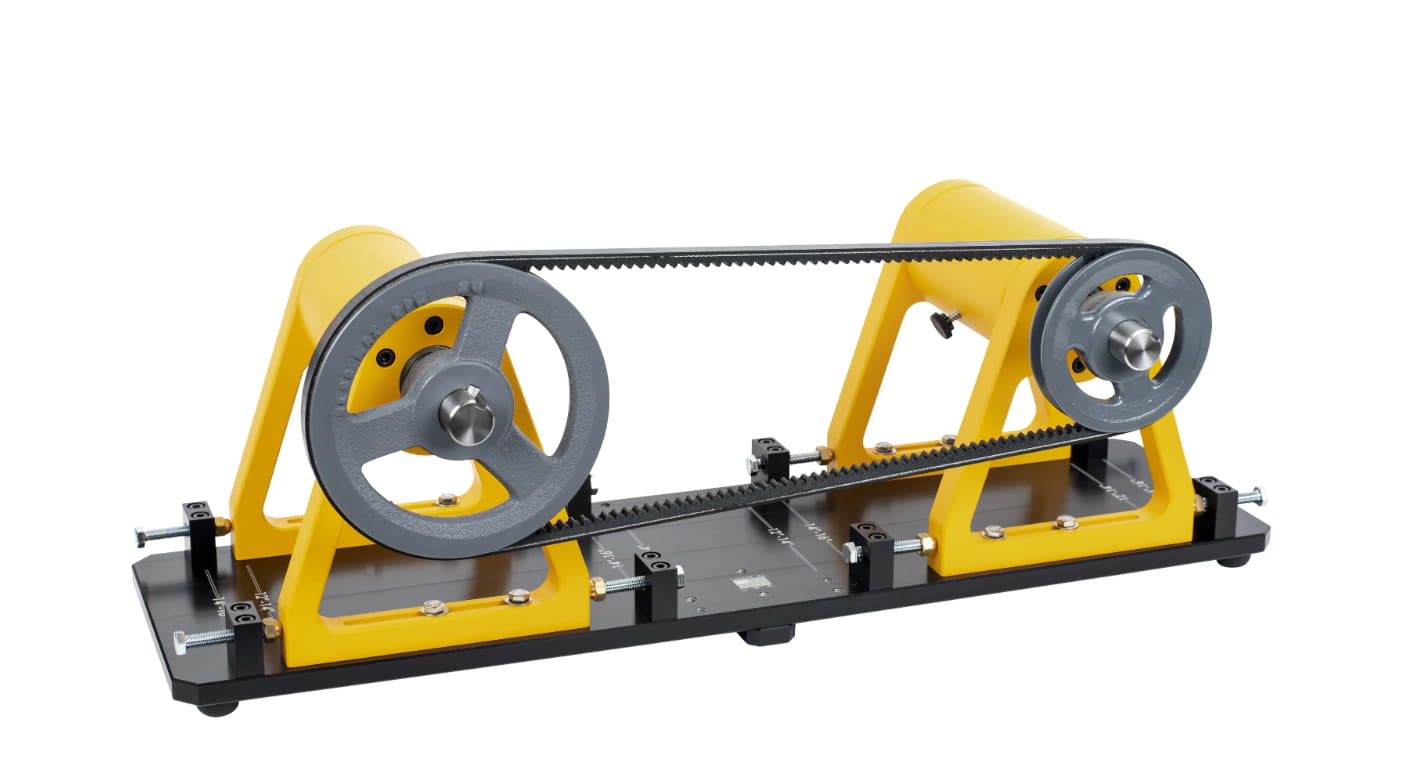

Imagine your car’s engine running at full throttle, but the wheels are barely moving. The culprit behind this scenario might be a misaligned belt pulley system. Belt pulley alignment is crucial for the efficient functioning of machinery, and if not maintained, it can lead to reduced performance, increased energy consumption, and even breakdowns. In this article, we’ll explore belt pulley alignment solutions that can help you optimize your machinery’s performance.

The Importance of Proper Belt Pulley Alignment

A belt pulley system consists of two or more pulleys connected by a belt. This system transfers rotational force from one pulley to another, driving various components in machinery such as motors, fans, pumps, and generators. When these pulleys are misaligned, the belt experiences uneven tension and wear, which can result in:

Reduced Efficiency:

Misaligned pulleys cause belts to slip, reducing the transfer of energy and leading to decreased performance.

Increased Energy Consumption:

As belts slip and struggle to maintain grip, the machinery consumes more energy to compensate for the loss of power.

Premature Wear and Tear:

Uneven tension on the belt leads to accelerated wear, shortening its lifespan and increasing maintenance costs.

Increased Noise and Vibration:

Misalignment can cause belts to vibrate, creating noise and potentially damaging other components.

To avoid these issues and keep your machinery running smoothly, it’s essential to invest in effective belt pulley alignment solutions.

Laser Alignment Tools: The Precision Solution

Laser alignment tools are the gold standard for achieving precise belt pulley alignment. These tools use laser beams to accurately measure the alignment of pulleys, ensuring that they are perfectly parallel and properly positioned. Some benefits of using laser alignment tools include:

-

High Accuracy:

Laser alignment tools offer unparalleled precision, allowing you to achieve optimal alignment and reduce energy consumption.

-

Ease of Use:

These tools are user-friendly and often come with intuitive software for quick and straightforward measurements.

-

Time-Saving:

Belt alignment tools provide instant feedback, enabling you to make adjustments on-the-fly and significantly reducing downtime.

Proper Installation and Maintenance: The Foundation of Alignment Success

Regardless of the alignment method you choose, proper installation and maintenance are key to ensuring long-lasting, efficient belt pulley performance. Here are some best practices to keep in mind:

-

Regular Inspections:

Regularly inspect your belt pulley system for signs of wear, misalignment, and other potential issues.

-

Scheduled Maintenance:

Follow your equipment manufacturer’s recommended maintenance schedule to keep your machinery in optimal condition.

Conclusion:

Belt pulley alignment is an essential aspect of machinery maintenance that should not be overlooked. By investing in the right tools and following proper installation and maintenance practices, you can streamline your belt pulley system, increase efficiency, and reduce costs.

Copyright © Rain Stone LLC All Rights Reserved